PRODUCTS

Taper drill rods

The tapered drill rod is evolved from the integral drill rod,and the effective length of the tapered drill pipe starts from the head of the drill pipe and ends at the collar. Generally, the length of the drill pipe is 0.6 meters to 3.6 meters.

keyword:

Taper drill rods

Categories:

In addition to the following common specifications,can produce a variety of special specification according to customers’different requirements.

Products Introduction

Tapered drill equipment also provides a hexagonal chuck section to provide leverage for the rotation chuck bushing, which usually has a forged collar to maintain the proper shank striking face position in the rock drill, and match a tapered bit at the socket end. With higher faster penetration, straighter holes, longer service life and lower cost per meter drilled than integral steel, tapered drill equipment is grabbing market share from integral drill steel, especially in mining applications and the dimensional stone industry.

1. The ordinary connection taper degree is 7º, 11º and 12º, other degrees like 4.8º and 6º are also available;

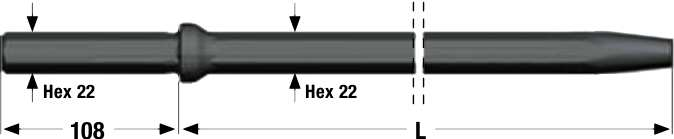

2. The ordinary shank is Hex22 × 108mm, Hex25 × 159mm and other styles are also available if upon customers’ request;

3. The rod length must be specified in order;

4. In order to adapt to different rock conditions, the drill rod is selected by users.

5.The ordinary material is 55SiMnMo.

How to order? Bit Diameter + Taper Degree + Socket Diameter

Different rock formations and rock drills require different taper angles. When drilling with high impact hydraulic rock drills in medium-hard to hard and abrasive rock formations, a wide taper angle is normally used. Taper angles of 11º and 12º are normally used on modern drill rigs. For low impact rock drills and softer rock formations, a narrow taper angle of seven degrees is used. A 7º angle can also be used if bit spinning is a problem when using 11 and 12-degree equipment. In addition, a 4.8º (also 4º46’) angle is ideal for soft rock when you're using pneumatic or hydraulic drill rigs - to prevent bits from spinning or becoming detached.

Consult immediately

If you are interested in our product, please leave your email, we will contact you as soon as possible, thank you!

Related products