PRODUCTS

Extra strength type

Expansive mortar is often preferred in situations where the use of explosives is impractical or prohibited due to safety concerns, environmental regulations, or nearby structures. It is commonly used in applications such as rock and concrete demolition, quarrying, concrete cutting, and splitting large blocks of stone or concrete. Additionally, expansive mortar is non-toxic and does not produce harmful fumes, making it a safer alternative to traditional blasting methods.

keyword:

Extra Strength

Categories:

In addition to the following common specifications,can produce a variety of special specification according to customers’different requirements.

Safety Precaution

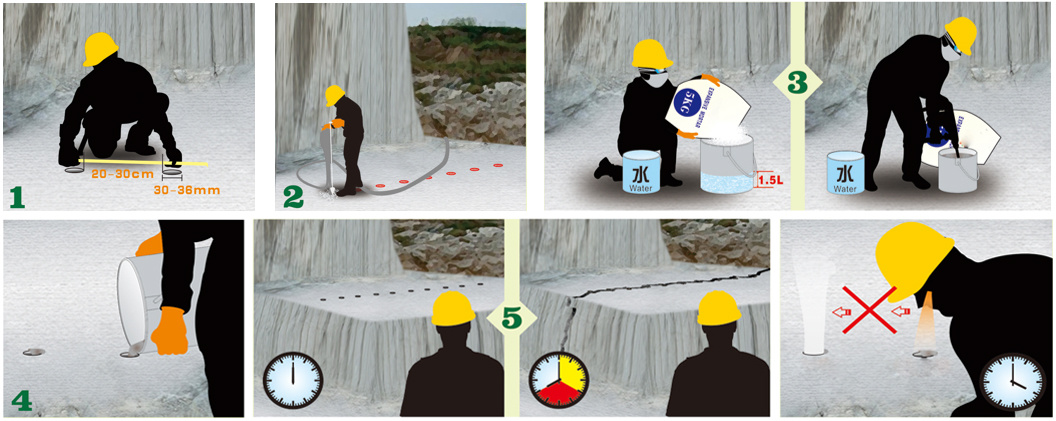

1.Make sure that everyone working with Expansive Mortar understands the possibility of blowouts,and has read the technical instructions thoroughly.

2.Expansive Mortar is a highly alkaline product,pH reaches 13 after contact with water and can cause severe irritation mucous membranes,especially eyes.Skin and eye contact with Expansive Mortar must be rinsed off with large amounts of cold water immediately without rubbing.Consult a doctor quickly.

3.Must wear safety goggles and rubber gloves during Expansive Mortar handling,mixing and filling.Dust-proof mask is recommended in poorly ventilated areas such as tunnels or mines.

4.Plug the holes immediately after filling and cover the holes with straw mat.Keep your face away from the holes filled by mortar.Stay away from filled holes at least 3 hours after filling to avoid blow-out shot.Keep people away from job site after filling.

5.Warm or bubbling mortar is forbidden to fill into holes.Once filled holes start to smoke or steam,that is the sign.

Products Introduction

Expansive mortar is a soundless and safe demolition agent which is quite different from ordinary demolition agents such as explosives and dangerous materials.It is suitable for rocks,reinforced or unreinforced concrete in both large jobs and small projects.

|

|

Traditional |

Extra Strength |

Large Hole |

|

Cracking time |

6hours~12hours |

6hours~12hours |

24hours~48hours |

|

Cracking size |

5mm~10mm |

5mm~20mm |

5cm~10cm |

|

Distance |

300×300mm |

400×400mm |

700×700mm~1300×1300mm |

|

Kiln remperature |

900c |

1500c |

1450c |

|

Hole diameter |

34mm |

34mm |

90mm~130mm |

|

Water distribution |

1.4L/5kg |

1.2L/5kg |

1.5L/kg~1.6L/kg |

How to Use

Temperature and relevant type

|

Type |

Performance |

Environment |

|

|

Pressure coefficient(km/c㎡) |

Reaction(split)time(hours) |

Temperature |

|

|

SCA-1 |

400-800 |

3hours~6hours |

25℃~40℃ |

|

SCA-2 |

400-800 |

4hours~8hours |

10℃~25℃ |

|

SCA-3 |

400-800 |

6hours~12hours |

5℃~15℃ |

|

SCA-4 |

400-800 |

12hours~24hours |

-5℃~10℃ |

Packing

Consult immediately

If you are interested in our product, please leave your email, we will contact you as soon as possible, thank you!

Related products